AKP Aiken Machinery invites you to visit the 2022 ITES Shenzhen Industrial Exhibition for guidance!

- Categories:Company News

- Time of issue:2022-06-15 16:33

AKP Aiken Machinery invites you to visit the 2022 ITES Shenzhen Industrial Exhibition for guidance!

- Categories:Company News

- Time of issue:2022-06-15 16:33

Invitation card

AKP Aiken , will attend the 2022 ITES Shenzhen Industrial Exhibition, we will display A3MT series high pressure machine tool cooling pump, A3SS series spindle center water outlet system and other products at the exhibition, looking forward to your visit !

Venue: Shenzhen International Convention and Exhibition Center

Time: 2022.7.5-7.8

Booth No.: 5U55

Exhibit content

AKP Aiken, the exhibits that will be exhibited at the ITES Shenzhen Industrial Exhibition this time are:

1. A3MT - E high pressure machine tool cooling pump

2. A3MT - D high pressure machine tool cooling pump

3. A3SS - XT 2 spindle center water outlet system

4. A3SS - XT4 spindle center water outlet system

5. Vertical skid for A3MT - D 6 high pressure machine tool cooling pump

Exhibit introduction

1. A3MT-E high pressure machine tool cooling pump and A3MT-D high pressure machine tool cooling pump

AKP Aiken, high pressure machine tool cooling pump is ideal for conveying coolant, cooling oil, grinding fluid, grinding oil and other cooling lubricants at medium and high pressure A high-precision three-screw pump product, which is widely used in CNC machining centers, CNC drilling and milling gantry machining machines, gear grinding machines, crankshaft grinding machines, and special machine tools for mass manufacturing of auto parts. However, when there are special abrasive particles in the pumped medium, there is a danger of premature wear and performance failure, manifested as insufficient flow, insufficient pressure, increased noise and vibration, etc. AKP Aiken adopts a unique hardened material coating on the screw pair of its A3MT series machine tool cooling pump, and improves the wear-resistant lining of ceramic hardening treatment, thus greatly prolonging the cooling of AKP Aiken high-pressure machine tools. life cycle of the pump. Considering the particularly harsh operating conditions and harsh applications, for example, grinding or machining batch castings or forged castings such as cast steel with corundum or CBN during gear grinding and crankshaft grinding applications, pumping overruns may still occur. The possibility of early wear and failure, the necessary sophisticated filter design and filter precision configuration are the basic guarantee of the pump life cycle and the basic conditions for the normal operation of the AKP Aiken high-pressure machine tool cooling pump.

2. A3SS-XT2 open center water outlet system

For high-end manufacturing industries such as CNC machine tools and auto parts, if you want to obtain better product quality, good equipment utilization, and reduce tool wear, the high-pressure unit of the spindle center water outlet can test your energy saving and lowering. To meet the consumption goals and requirements, Aiken's A3SS system is mainly equipped with A3MT series high-pressure screw pumps, with a pressure of up to 150 kg and a flow of up to 800 L/min. The main configuration is a backwash type bag filter, the filtration precision can reach 5-25 microns, and the working life of the screw pump can be extended when used.

3. A3SS-XT4 man-machine interactive central water outlet system

The touch screen interface controls the operation and signal feedback of the entire system, and can intuitively check the liquid level height, high-pressure pump operation, low-pressure pump operation, filter operation, etc.

Before starting the machine, the user can set 8 pressure values by themselves, and the required pressure can be selected according to the size of the tool during work.

After the working pressure value is set, the system will automatically adjust the water flow and pressure according to the size of the tool to stabilize the set pressure value.

During the commissioning process, the entire system can be switched to manual mode, and the high-pressure pump, lift pump, backwash filter, etc. can be individually controlled in manual mode.

When a fault occurs, the main page will pop up a fault code, click on the fault code to enter the fault viewing page, and the operator can solve the current fault according to the fault code prompt, such as: water tank shortage; water temperature is too high; lift pump fault, etc., in case of internal fault Engineers can directly view the running status of a certain I/O point of the PLC, so as to analyze the cause of the failure.

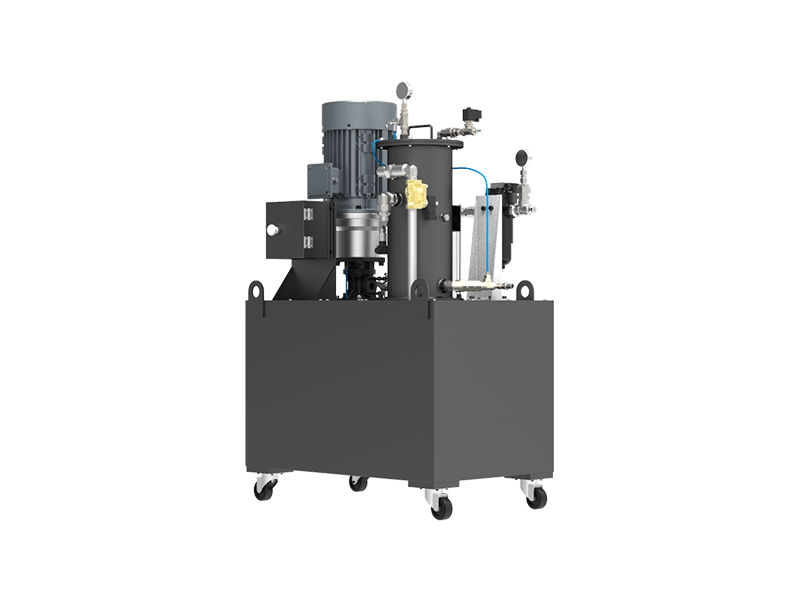

4. A3MT-D6 series high-pressure machine tool cooling pump vertical skids

can be flexibly purchased according to actual working conditions and functions, and the purchase of suitable accessories can save unnecessary costs, and the design version and design code can be provided when purchasing. Each accessory supply combination has a specific serial number, which is highly traceable; if there is no combination of the following accessories or accessories need to be replaced, communicate with the business manager in time

Related News

Time of issue 2022-05-06

Time of issue 2022-04-30

Time of issue 2022-04-25

AlKEN SCREW PUMP & SYSTEM

E-mail: cpo@akscrewpump.com

Add: BNo. 51, Huancheng West Road, Huizhou District, Huangshan City, Anhui Province

Scan the QR code

CopyRight © 2022 Huangshan Aiken Machinery Manufacturing Co., Ltd. 皖ICP备13007750号-4

皖 34100402000256号

SEO Sitemap Privacy protection Legal notices Powered by:300.cn

Links: